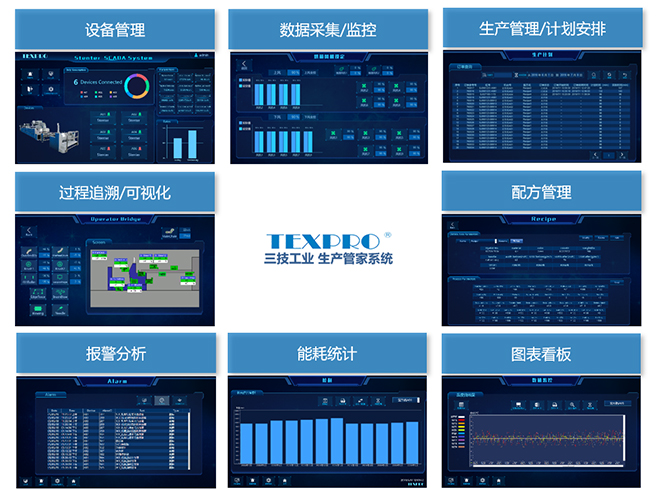

Simultaneously monitor multiple devices

Simultaneously monitor multiple devices, including device status, operating parameters, alarms, etc.

Real-time video monitoring

Provide video monitoring functions, such as real-time viewing of live video of the head and tail of the Stenter.

Setting parameters online

The process parameters can be modified online, and the recipe function is provided, and the parameters can be set with one button.

Energy consumption

The water, electricity, steam and other energy consumption data generated by the equipment operation are counted and associated with the batch to facilitate cost calculation, and alarms can be given when the energy consumption exceeds the set range.

Collect and store production data

Collect and store production data in real time for product issue tracking.

Associate with ERP

Associate with ERP, obtain order and batch information, automatically schedule production to achieve flexible production mode.

Personnel management

Management and audit tracking can be performed on personnel, such as traceability of designated batch production personnel, personnel authority, electronic signature, and operation record management.

Production Controlling System

Model:

Product introduction:Intelligent management, break the information isolated island

- Features

- Downloads

Contact

Contact CN

CN